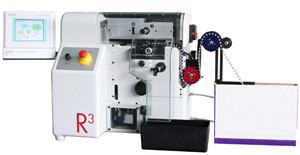

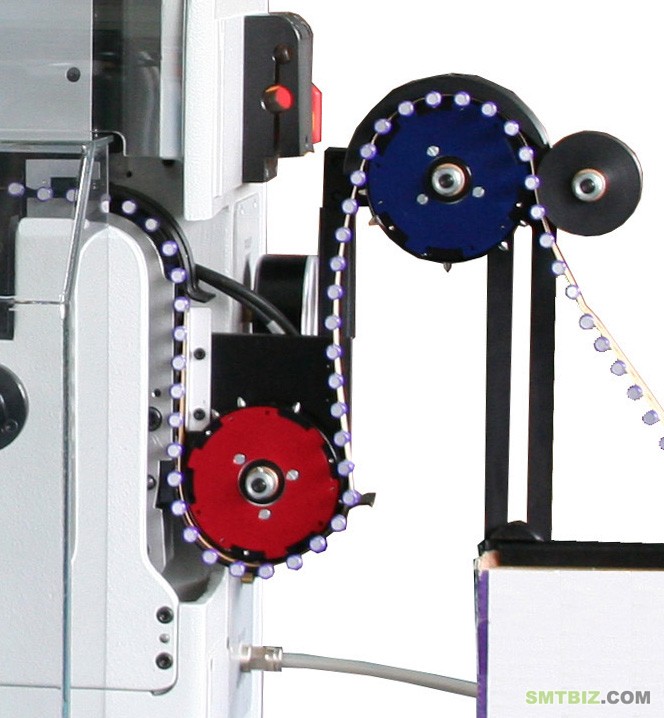

| Fully automatic cutting and bending machine for radial components |

The advantages of the R3 production machine:

- Without pull or stress on the components. Even the most delicate components are processed without damage.

- The first machine with continuous adjustment of different pitches 2.5 –15.0 mm

- Standard crimping shape applicable to all typical pcb’s

- Working with rolls and ammo packs

- Short crimping with optional tool

- Easy switch-over from 2 to 3-legs components

- Continuous adjustable crimping depth below pcb, and lead length

- Forward and reverse function

- Expand pitch up to 2.5 mm

- No equipment change, no special tool required and no supervision necessary

- SPS control unit with counter preselecion and automatic operation control

- Low maintenance required

- Silent operation

- Tape pitch from 12.7 to 15 mm with simple switching.

|

Art-No.: 18000.R3-MT

|

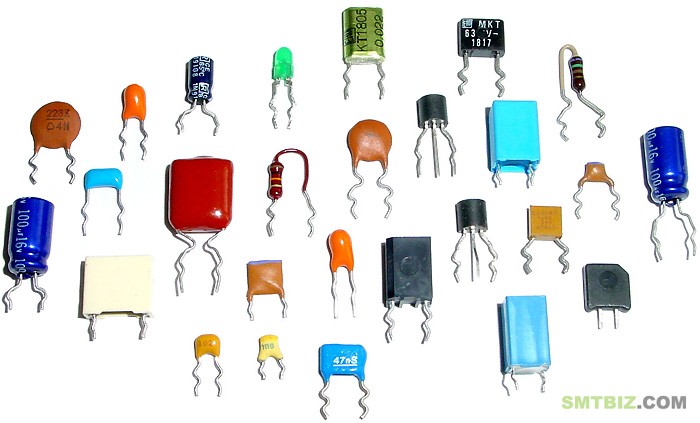

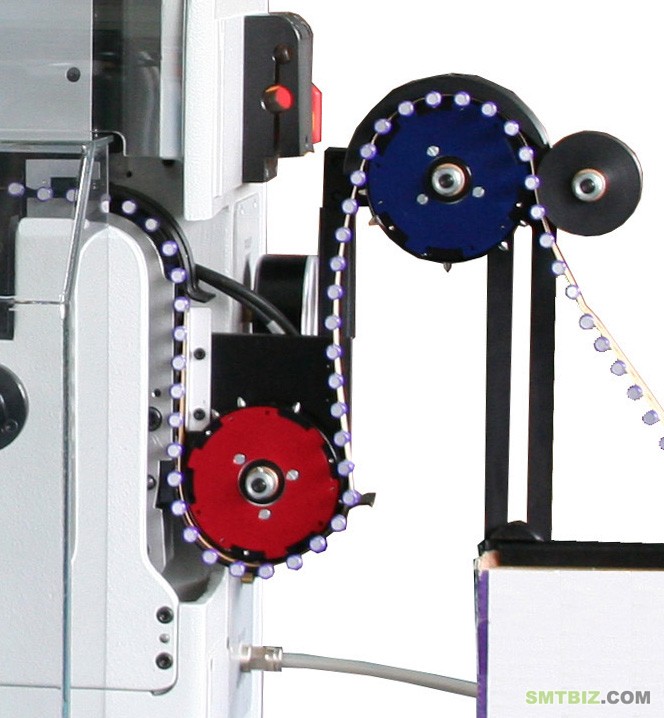

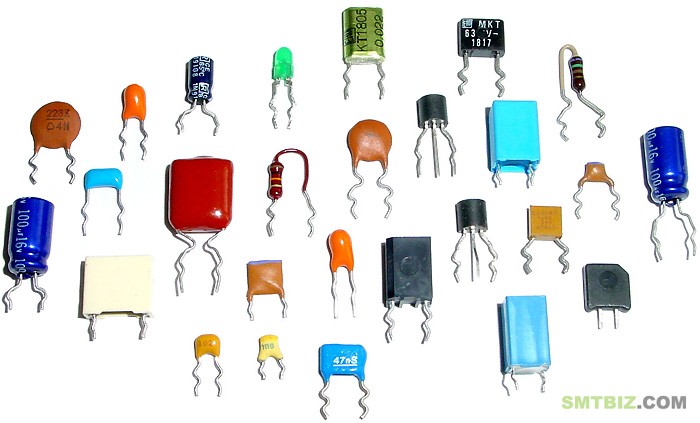

| Processing samples |

|

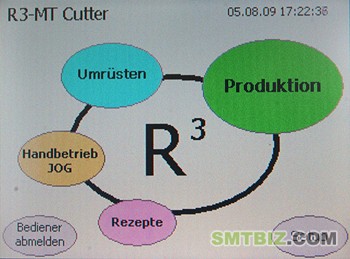

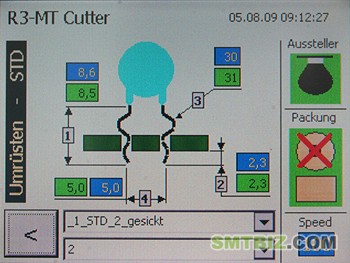

| Control unit properties |

|

The advantages of the SIEMENS Panel TP177B

- The setup values of the axis can be saved in a program.

- There are 6 different geometric forms shown in 6 individual databases.

- These 5 databases can each hold 200 programs.

- The axis numbers on the screen correspond to the written numbers on the machine. This gives the operator a better overview.

- Process reliability: The production can just be started if the positions of all axes correspond to the position of the chosen program.

- Also during production the axes are permanently checked, is the position of one axe changing, the machine stops its process.

- New programs can be written very simply. There is one button needed to write all position data’s into the recent recipe.

- Option: A Barcode reader over USB can be used to call up in a simple way the program of your choice.

- Error and failure messages give detailed information about what is happening in the machine and what has to be done to avoid or to solve the problem.

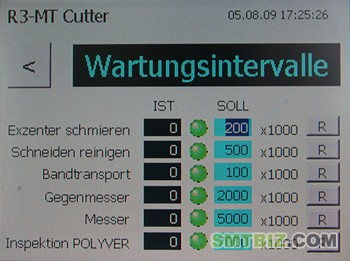

- The Maintenance-Assistance supports the operator to keep the maintenance of the machine in schedule. The maintenance is calculated by the amount of components produced. The operator receives the messages as soon as the counter overlapses. The counters can be reset and all changed to exactly fit the application.

|

|

| Technical Specification - Tool Specification |

|

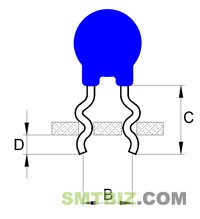

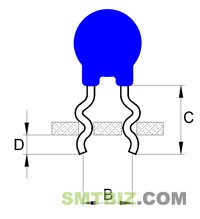

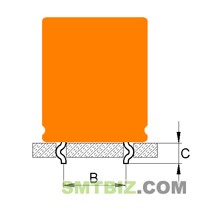

Tool I - Distance holding crimp

|

|

C |

Cutting length |

min 6mm |

| |

Lead diameter |

0.3 - 0.8mm |

| D |

Length below PCB |

1.1 - 2.4mm |

| B |

Pitch size |

2.5 - 15.0mm |

|

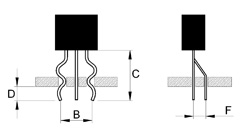

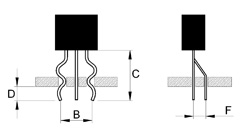

F |

Outline measurement |

2.5 mm |

| |

PCB size |

1.5mm |

|

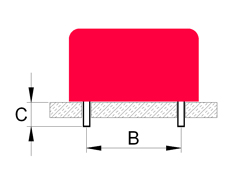

Tool II - Short holding crimp

|

|

C |

Cutting length |

min 3.0 mm |

| B |

Pitch size |

2.5 - 15.0mm |

|

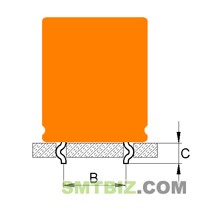

Tool III - only cutting (short cutting)

|

|

C |

Cutting length |

min 2.5 mm |

| |

Lead diameter |

0.3 - 1.0 mm |

| B |

Pitch size |

2.5-27.5 mm |

|

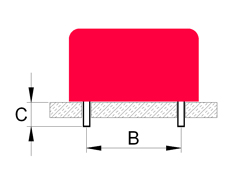

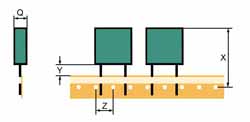

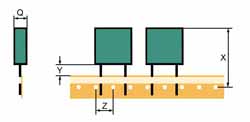

Tape specification

|

|

Q |

Component width |

max 20.0 mm |

| X |

Component height |

max 50.0 mm |

| Y |

Lead length |

min 5.0 mm |

| Z |

Tape hole pitch |

12.7 und 15.0 mm |

| Special shapes on request |

本公司经销

电阻成型机

功率晶体成型机

散装电容成型机

带式单边零件成型机

手摇编带元件切脚机

全自动编带元件成型机

气动元件成型机

全自动散料LED灯成型机

自动切脚机

全自动编带电阻(二极管)成型机-UK型

手摇散带通用电阻(二极管)成型机-F型

全自动带式电阻(二极管)成型机-F型

全自动带式电阻(二极管)成型机-U型

全自动带式电阻(二极管)成型机-FK型

全自动带式电阻(二极管)剥纸带成型机-FK型

自动管装三极管成型机

自动管装晶体(MOS管)成型机(20管自动下料)

全自动散装可控硅成型机